فهرست مطالب

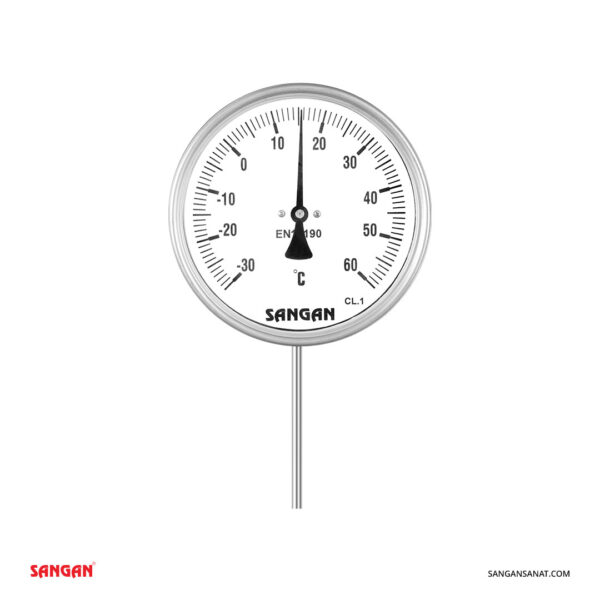

Gas-filled Thermometer TG18

The Gas-filled Thermometer TG18 is an advanced temperature measurement device used in industrial environments and sensitive processes. This type of thermometer utilizes gas expansion technology to provide high accuracy and resistance to challenging environmental conditions. The TG18 gas thermometer is particularly useful in industries that require precise temperature measurement in fluctuating conditions.

Operation

The gas temperature gauge TG18 uses a sealed gas system where temperature changes cause the gas inside the system to expand or contract. These changes are transferred to the internal mechanism of the thermometer, which displays the desired temperature either through a needle or a digital display. This technology makes the gas thermometer resistant to thermal shocks and vibrations.

Applications

- Oil and Gas Industry: Temperature monitoring in pipelines and pressure equipment

- Chemical Industry: Temperature measurement in corrosive and reactive environments

- Power Plants: Temperature control in steam systems and turbines

- Food Industry: Precise temperature monitoring in production and packaging processes

- Pharmaceutical Industry: Used in drug production lines to maintain hygiene standards

Advantages of Using the Gas-filled Thermometer TG18:

- High Accuracy: Precise temperature measurement under variable conditions

- Long Lifespan: Resistant to corrosion, thermal shock, and vibrations

- No Power Source Required: Operates independently without electricity or batteries

- High Durability: Designed to withstand harsh environmental conditions

- Easy Readability: Large display and clear pointers

Main Components of the TG18 Gas Thermometer

- Thermometer Body: Made of stainless steel for environmental resistance

- Gas System: Includes a reservoir and pipes for transferring temperature changes

- Display: Analog or digital display to show temperature

- Process Connection: Easy installation on industrial equipment

Design and Production Standards: The gas temperature gauge TG18 is designed and produced according to international standards such as ANSI/ASME B40.100 and ISO 9001. These standards ensure the product’s accuracy, safety, and performance in various conditions.

Important Considerations in Choosing a Gas Thermometer

- Temperature Range Selection: Check the temperature range required for the specific application

- Body Material: Choose materials resistant to corrosive fluids or high temperatures

- Connection Type: Pay attention to the thread or flange type for easy installation

- Display Size: Choose the display size based on the viewing distance

Maintenance

- Regular Cleaning: Prevent dust or corrosive materials from accumulating on the body

- Regular Calibration: Maintain the accuracy and performance of the thermometer

- Visual Inspection: Ensure the integrity of the body and connections

- Avoid Thermal Shock: Use within the temperature range specified by the manufacturer

Conclusion

The Gas-filled Thermometer TG18, with its durable design, high accuracy, and broad application in various industries, is one of the best choices for temperature measurement in industrial environments. Due to its independent operation, easy installation, and long lifespan, it helps reduce maintenance costs and enhance the efficiency of industrial systems. Proper usage and regular maintenance can lead to increased productivity and optimal performance of this device.