فهرست مطالب

Flanged Thermowell

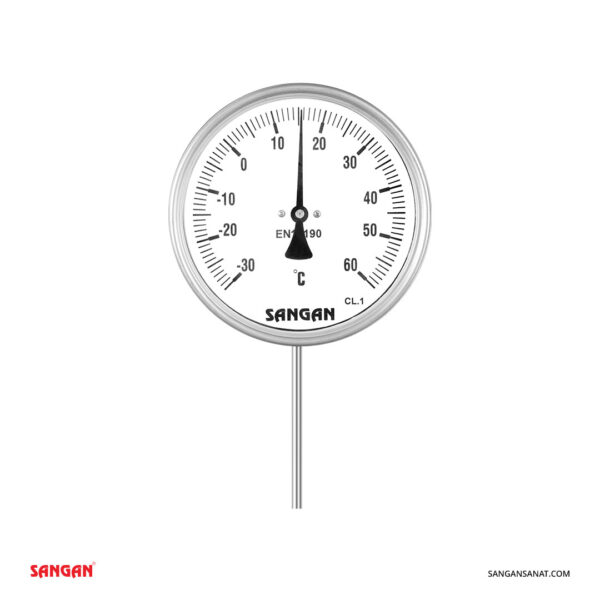

A flanged thermowell is an essential tool in various industries, designed to protect temperature sensors from harsh conditions such as high pressure, high velocity, and corrosive materials. In addition to protecting the temperature sensor, it also allows for sensor replacement without needing to stop the process. The flanged thermowell is available in various models, including W91, W101, and W111, each with its own specific features and applications. This article will explore the flanged thermowell, its characteristics, and the different types of this tool.

Function of Thermowell

The thermowell protects the temperature sensor from high-pressure environments, high velocities, and corrosive materials. It keeps the sensor safe from conditions that could potentially cause damage while also assisting in accurate temperature measurement. The flanged thermowell is especially used in industrial systems with harsh conditions to maintain the performance and longevity of temperature sensors.

This tool uses a flanged layer for installation in piping systems or industrial equipment, making its installation easy and quick. Different types of flanged thermowells are available to meet varying needs.

Types of Flanged Thermowell

-

W91: Stepped The W91 flanged thermowell is designed with a stepped shape and is suitable for environments requiring the passage of pipes with different diameters. This type of thermowell, with a larger cross-sectional area at the end, allows for connection to larger pipes.

-

W101: Tapered The W101 flanged thermowell is designed with a tapered shape, ideal for creating a stronger and more resistant connection to high-pressure systems. This design is particularly suitable for applications where resistance to intense forces is required.

-

W111: Straight The W111 flanged thermowell, with a straight design, is used for standard and general applications. This thermowell is appropriate for industrial environments requiring basic protection of temperature sensors from standard pressure and corrosion conditions.

Advantages of Using a Thermowell

-

Protection of the temperature sensor from pressure and corrosive materials The thermowell effectively protects temperature sensors from high pressures, high velocities, and corrosive materials. This feature is especially vital in industries dealing with chemicals and corrosive substances.

-

Extended lifespan of the temperature sensor By protecting the sensor, the thermowell increases its lifespan and prevents early failures. This feature helps reduce maintenance costs and increases the efficiency of industrial systems.

-

Accuracy in temperature measurement The thermowell helps maintain the accuracy of temperature sensors in harsh conditions, ensuring precise temperature measurements in sensitive processes.

-

Sensor replacement without stopping the process One of the key benefits of the thermowell is the ability to replace the temperature sensor without needing to stop the process. This feature reduces downtime costs and enhances the efficiency of industrial systems.

-

Variety of materials, sizes, and dimensions Thermowells are produced in various materials, sizes, and dimensions, giving users the flexibility to choose the most suitable model for their specific application. This versatility makes this tool suitable for a wide range of industries.

Applications

-

Oil and Gas Industry In the oil and gas industry, thermowells are highly useful for protecting temperature sensors from high pressure and corrosive materials. This tool is widely used in oil and gas extraction and transportation processes.

-

Chemical and Petrochemical Industries In these industries, protecting temperature sensors from corrosive chemicals and high temperatures is of utmost importance. With its robust design, the thermowell performs reliably in such environments.

-

Food and Pharmaceutical Industries In the food and pharmaceutical industries, the thermowell is used as a tool for precisely monitoring temperature and maintaining product quality. Its protection of temperature sensors makes it highly effective in sensitive production processes.

-

Power Plants In power plants, temperature plays a crucial role in energy production processes. Thermowells help in precise temperature measurement of critical systems, aiding in energy production.

-

HVAC Systems In HVAC systems, thermowells are used to control temperature and pressure. They help maintain optimal performance of heating and ventilation systems.

How to Choose the Right Flanged Thermowell

Choosing the right flanged thermowell depends on factors such as the type of system, operating pressure, and the environmental conditions. A proper selection can enhance the efficiency and longevity of temperature measurement equipment.

Maintenance and Repair of Flanged Thermowells

Flanged thermowells generally require little maintenance, but the following steps can ensure optimal performance:

- Periodic checks to ensure there is no damage or wear on the thermowell.

- Cleaning the thermowell from external contaminants and deposits.

- Regular inspection of the flange and connections.

Conclusion

The flanged thermowell is a crucial tool for protecting temperature sensors in various industries. With models like W91 (stepped), W101 (tapered), and W111 (straight), this tool can meet the needs of various industries. By choosing the right flanged thermowell, you can ensure precise performance, long service life, and the safety of temperature sensors.