فهرست مطالب

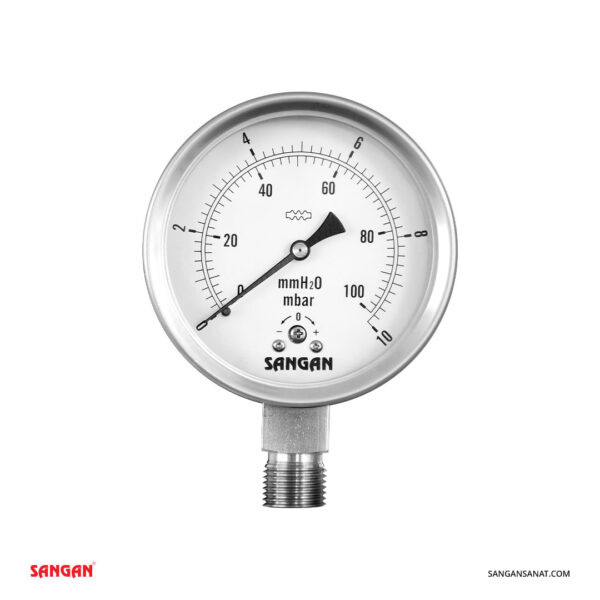

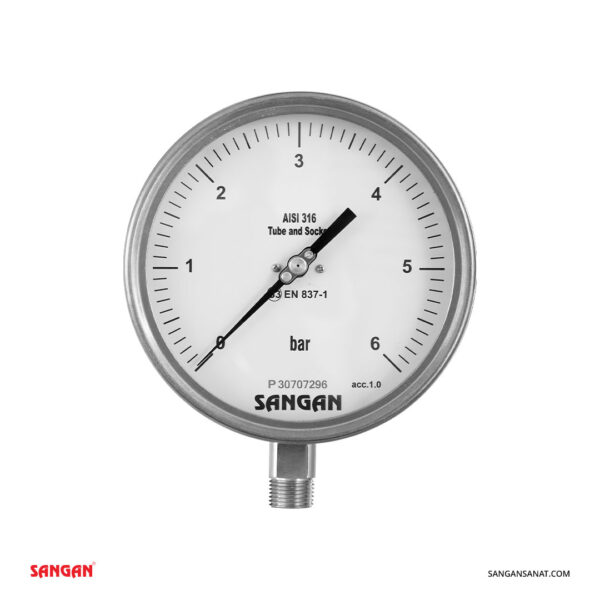

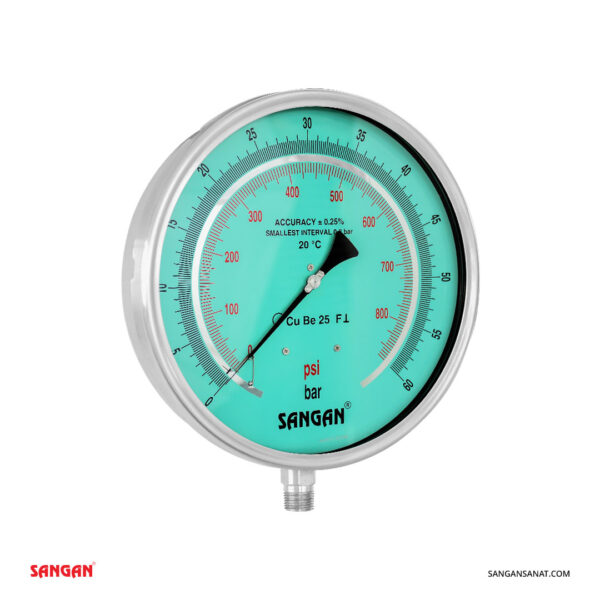

Phenolic Pressure Gauge PG21

The Phenolic Pressure Gauge PG21 is an advanced tool for measuring pressure in industrial systems. Due to its unique design and use of phenolic materials, it offers high resistance and enhanced safety in harsh conditions. This device is specifically designed for environments that require tools resistant to pressure, impact, and temperature. In this article, we will explore the details and applications of the Phenolic Pressure Gauge PG21, highlighting its key benefits and features.

Design and Performance

The Phenolic Pressure Gauge PG21 uses phenolic materials for its main body. These materials are considered some of the best options for industrial tools due to their high resistance to heat, chemicals, impact, and scratches. The internal diaphragm of the device is designed to accurately measure the applied pressure and display it on either an analog or digital display.

Phenolic materials act as strong insulators, ensuring the PG21 pressure gauge performs optimally even in environments with high temperatures or excessive humidity. This gauge is particularly ideal for systems that deal with corrosive materials or harsh environmental conditions.

Key Features

-

High Safety in Sensitive Environments

The phenolic body design makes this gauge safe from risks associated with high temperatures and pressures, preventing potential damage. -

High Chemical Resistance

Phenolic materials are resistant to corrosion and chemical reactions, making the PG21 pressure gauge more effective in chemical and corrosive environments. -

Long Lifespan and Durable Design

The robust body of the device prevents scratches, impacts, and environmental damage, ensuring the pressure gauge has a long useful life. -

High Accuracy in Pressure Measurement

The internal system of the PG21 pressure gauge uses a sensitive diaphragm to measure pressure with high accuracy and provide reliable results. -

Easy Installation and Variety of Sizes and Models

This gauge is designed for simple installation and use. Various models are available for different industrial systems.

Applications of the Phenolic Pressure Gauge PG21

-

Oil and Gas Industry

In the oil and gas industry, precise pressure measurement in pipeline and tank systems is crucial. The PG21 pressure gauge, with its high resistance to chemicals and extreme pressures, is widely used in these industries. -

Chemical and Petrochemical Industries

In environments dealing with corrosive and hazardous chemicals, the gauge ensures safe and reliable performance due to its resistant body. -

HVAC Systems

In HVAC systems, precise pressure control is essential for optimal performance. The PG21 pressure gauge, with its high accuracy and resistance to various environmental conditions, is an important tool in these systems. -

Pharmaceutical and Food Industries

In the pharmaceutical and food industries, where maintaining hygiene standards and pressure control accuracy is essential, the PG21 pressure gauge is trusted as a reliable tool. -

Power Plants and Energy Production

In power plants and energy production systems, accurate pressure measurement in various sections is crucial for safety and efficiency. Due to its high resistance and measurement accuracy, the PG21 pressure gauge is an ideal choice for these industries.

How to Choose the Right Phenolic Pressure Gauge

When selecting the most suitable model of the pressure gauge, consider the following factors:

- Working Environment Type: Does your environment include corrosive materials or extreme temperatures?

- Pressure Range Needed: Determine the maximum pressure of the system and select the appropriate model.

- Connection and Installation Type: What kind of connections does your piping system or existing equipment require?

These factors will help you choose the best model of the phenolic pressure gauge and optimize the performance of your system.

Maintenance and Care of the Phenolic Pressure Gauge

Proper maintenance of the phenolic pressure gauge can help extend its lifespan. Key maintenance tips include:

- Regularly check the performance and calibration of the device to ensure accurate measurements.

- Clean the body and diaphragm to prevent the buildup of dirt and corrosive materials.

- Avoid subjecting the device to heavy impacts or environmental conditions that exceed its capacity.

Conclusion

The Phenolic Pressure Gauge is a durable, accurate, and safe tool for measuring pressure in industrial environments. With features such as a phenolic-resistant body, high resistance to corrosive materials, high accuracy, and long lifespan, it is recognized as one of the best options for various industries. Proper selection and maintenance of this gauge can enhance system performance and reduce maintenance costs.