Flushing Ring AC55

The Flushing Ring (Flushing Ring) is an essential component in many industrial systems, used for continuous cleaning and maintaining optimal performance of equipment. It is particularly used in manufacturing processes and sensitive equipment such as pressure gauges and pressure measurement systems. This article discusses the features, applications, and advantages of the Flushing Ring AC55 to help users better understand this device.

What is the Flushing Ring AC55?

The Flushing Ring AC55 is a device designed for cleaning and cleaning pipelines and industrial equipment to prevent the buildup of materials and particles in process systems. This device is typically installed in pipelines exposed to chemicals or other liquids. Flushing Rings are specifically used to protect sensitive components such as pressure gauges and other measurement instruments. The AC55 model of Flushing Rings is known as an effective solution for cleaning and improving the performance of industrial systems.

Key Features of the Flushing Ring AC55

- Durable and Resistant Design

The Flushing Ring is designed for use in harsh industrial conditions. It is usually made of stainless steel or materials resistant to corrosion, which provides high durability and extended life in various environmental conditions. This feature makes the Flushing Ring ideal for use in chemical, petrochemical, oil and gas, and other sensitive industries. - Effective Pipeline Cleaning Ability

One of the key features of the Flushing Ring is its ability to effectively clean pipelines and equipment. This device continuously passes liquids or gases through the pipelines to remove particles and excess materials. This prevents blockages in pipes, pressure gauges, and other sensitive devices, enhancing the performance of industrial systems. - Reduction of Equipment Damage Risk

Using a Flushing Ring helps reduce the risk of damage to measuring equipment such as pressure gauges and thermometers. By preventing the buildup of particles and chemicals inside the pipes, Flushing Rings help protect these sensitive instruments and increase their lifespan. - Suitable for Various Industries

The Flushing Ring is suitable for use in a wide range of industries. Its applications include chemical, petrochemical, oil and gas, energy production, and other industrial processes. This device is particularly useful in environments where there is a risk of solid or chemical material accumulation in the pipelines. - Easy Installation and High Efficiency

The Flushing Ring is specifically designed for easy installation and high efficiency. This device can be quickly installed in existing systems and easily connected to other equipment. The installation process is designed to require minimal expertise, and it can be performed by technical teams in industrial environments. Additionally, this device is easy to maintain and does not require continuous inspection and repairs, reducing operational costs.

Applications

- Chemical and Petrochemical Industries

In the chemical and petrochemical industries, where liquids and gases flow through complex environments, the Flushing Ring AC55 plays an important role in cleaning pipelines. This device is especially useful in production processes where chemicals are continuously transferred through pipes. - Oil and Gas Industry

In the oil and gas industry, pipelines and fuel transfer systems require regular maintenance and cleaning. The Flushing Ring AC55 can effectively assist in cleaning oil and gas transmission pipelines and prevent blockages or reduced system efficiency. - Energy Production

In power plants and energy production systems, Flushing Rings are used to continuously clean and flush pipelines and sensitive equipment. This helps maintain optimal equipment performance and prevents unexpected shutdowns. - Water and Wastewater Systems

In water and wastewater systems, the Flushing Ring can be used for cleaning water transfer pipelines and preventing blockages. Regular cleaning can prevent the accumulation of organic or biological materials inside the pipes. - Pressure Gauges and Measurement Equipment

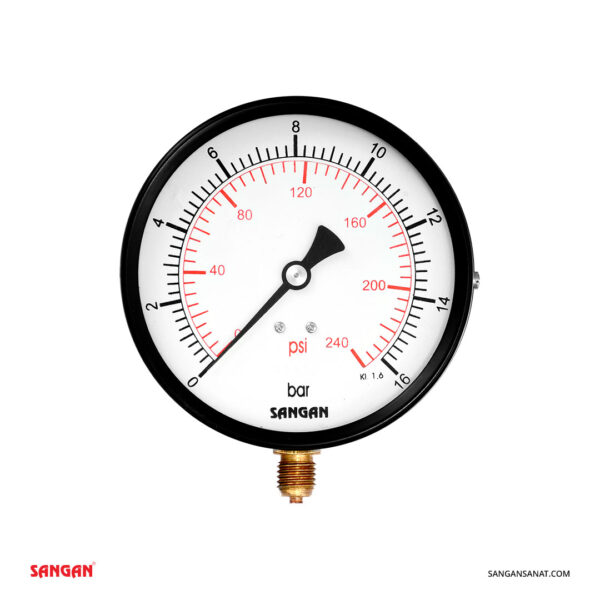

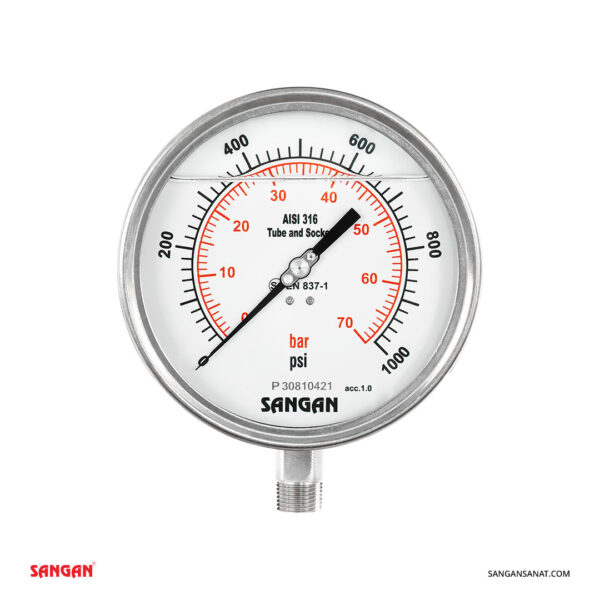

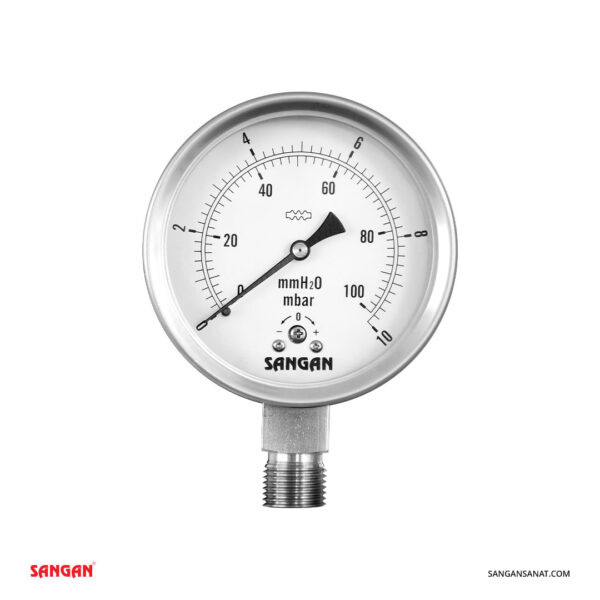

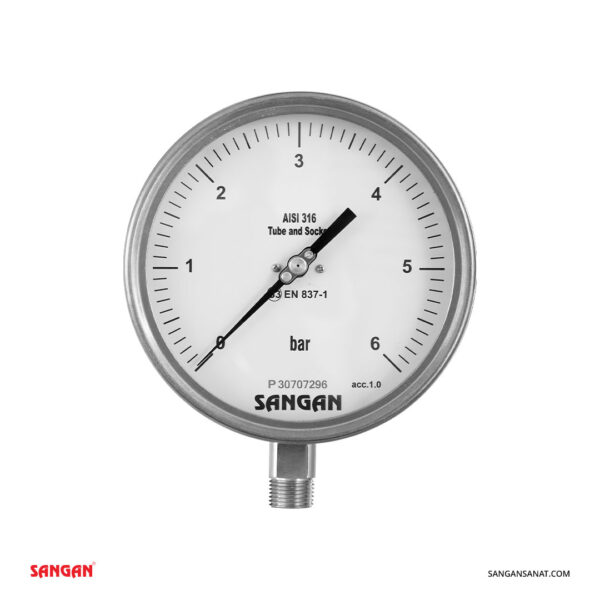

The Flushing Ring AC55 is especially designed to protect pressure gauges and other sensitive measuring equipment. By preventing the ingress of chemicals and particles into these instruments, it ensures their precise operation and longer lifespan.

Advantages of Using the Flushing Ring AC55

- Improved System Performance

Using the Flushing Ring helps systems operate more effectively. By continuously cleaning pipelines and preventing particle accumulation, system performance is enhanced, and blockages and potential failures are avoided. - Reduced Maintenance Costs

With the use of the Flushing Ring, the need for ongoing system repairs and maintenance is reduced. This device continuously cleans the pipes and prevents material buildup, which can lead to reduced repair and maintenance costs. - Increased Equipment Lifespan

Flushing Rings help protect sensitive equipment such as pressure gauges and extend their useful life. By preventing the entry of chemicals and particles into these instruments, their lifespan is prolonged. - Simplified Industrial Processes

Installing the Flushing Ring AC55 simplifies and enhances the cleaning process of systems. This device reduces the time and effort required for cleaning pipelines and equipment. - Time and Cost Savings

Due to its simple design and easy installation, the Flushing Ring AC55 requires minimal time to set up and use. This feature helps save time and operational costs.

Conclusion

The Flushing Ring AC55 is a vital tool for cleaning pipelines and equipment in industrial systems, especially in chemical, petrochemical, oil and gas, and energy production industries. With features such as a durable design, effective cleaning, protection of sensitive equipment, and easy installation, this device has become an excellent choice for improving system performance. If you are looking for an effective solution for cleaning pipelines and preventing blockages in industrial systems, the Flushing Ring AC55 is the best option.