فهرست مطالب

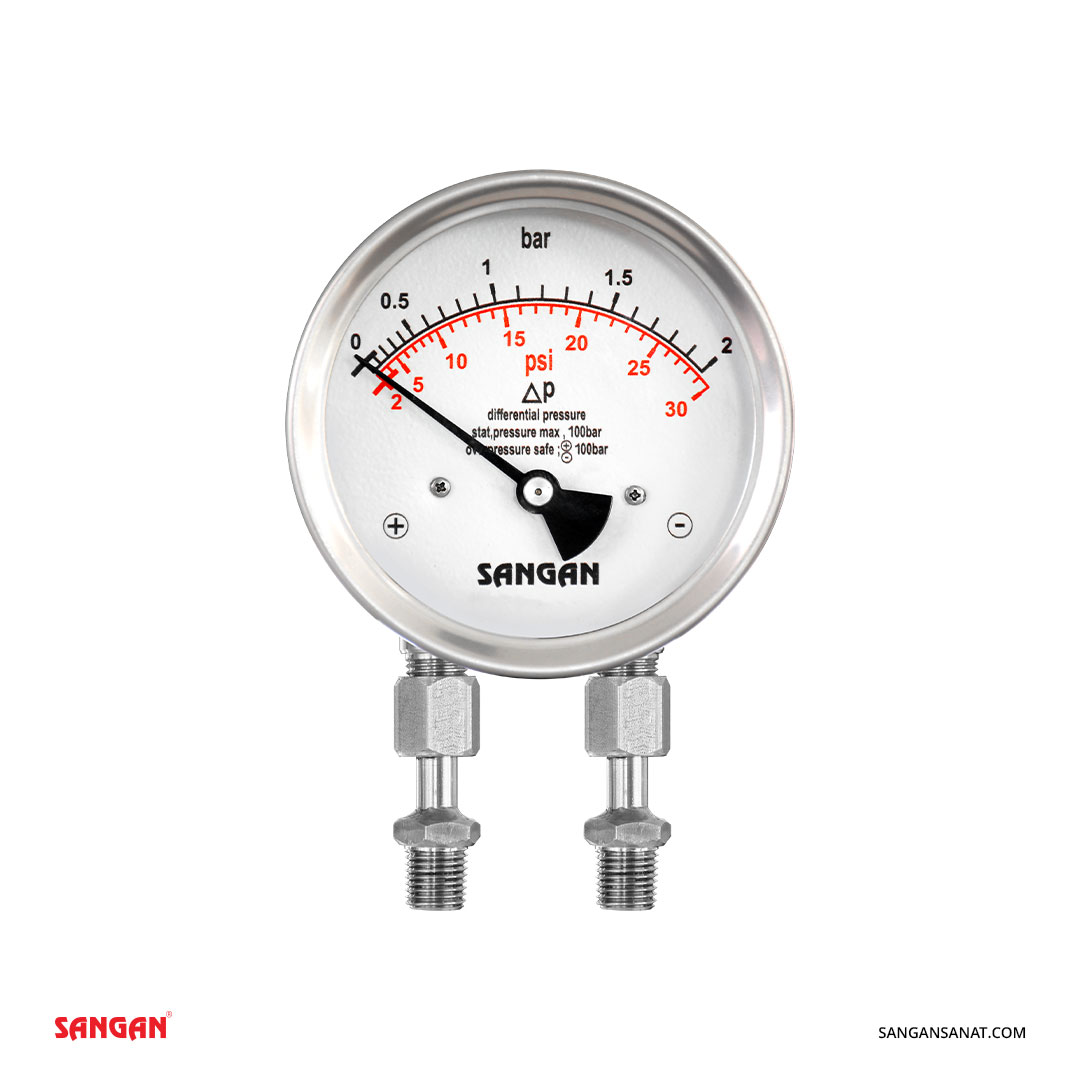

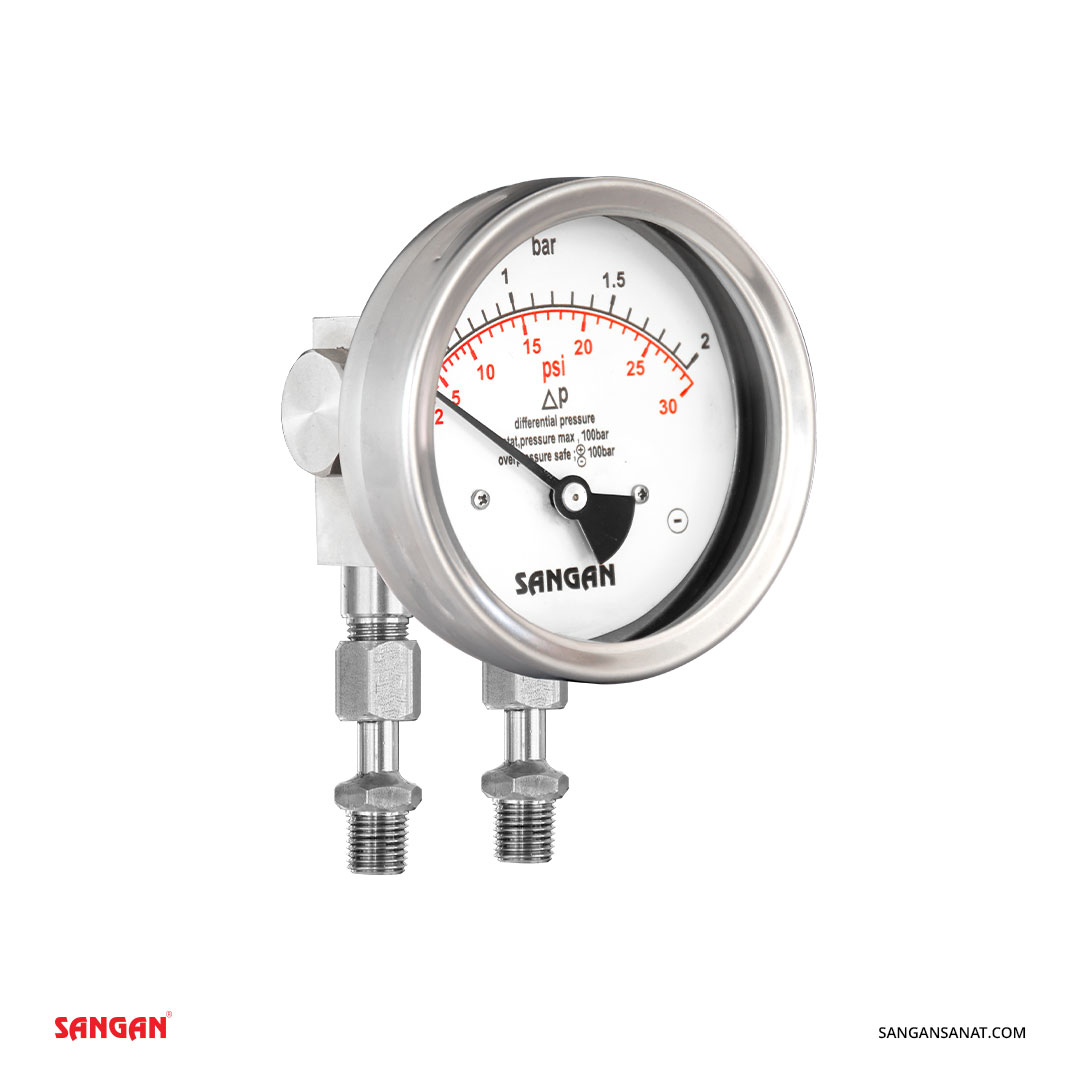

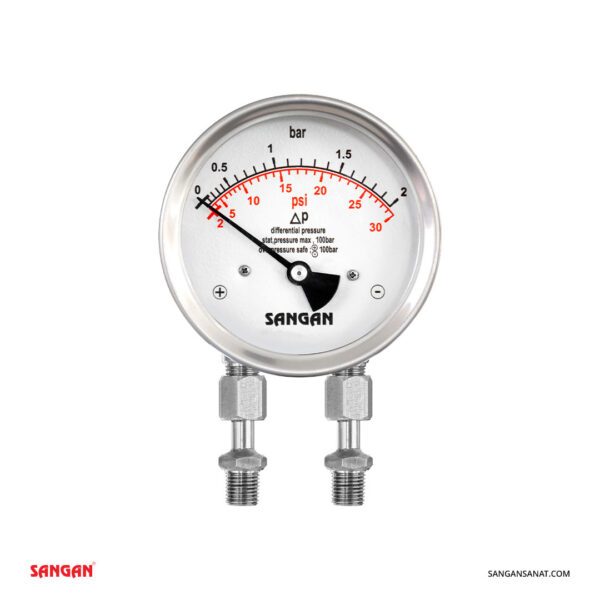

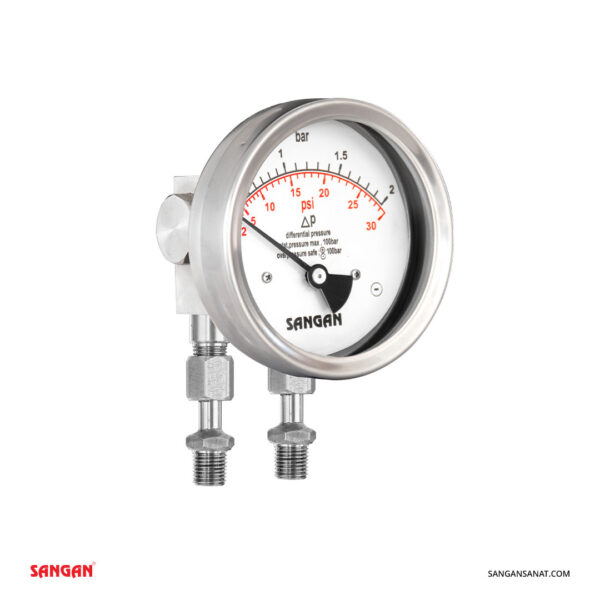

Piston Differential Pressure Gauge PG13-DPG

The PG13-DPG piston differential pressure gauge is an important tool used in various industries for measuring pressure and pressure differences in different systems. These devices are especially utilized in hydraulic, pneumatic, and other industrial equipment. This article will explore the features and benefits of using these gauges, as well as explain their performance and accuracy in various environments.

Operation

The PG13-DPG piston differential pressure gauge is specifically designed to measure the pressure difference between two points in different systems. These gauges use the mechanical principles of pistons to accurately measure the pressure differential. The piston inside the device moves and measures the pressure in both points of the system, displaying the results. These devices are highly accurate, making them ideal for use in sensitive industries such as oil, gas, and petrochemicals.

Advantages of Using the PG13-DPG Piston Differential Pressure Gauge

-

High Accuracy: One of the main advantages of these gauges is their high accuracy in measuring pressure. Due to the precise design of the pistons and the use of advanced technology, these gauges can measure pressure differences with millimeter precision. This feature is crucial in environments where extremely accurate measurements are required.

-

Resistance to Harsh Environmental Conditions: The PG13-DPG gauges are designed to operate under various environmental conditions, including high temperatures, humidity, and high pressures. This feature makes these gauges suitable for industries such as chemical and petroleum, where harsh conditions are common.

-

Wide Applications: These gauges are used in a variety of industries, including automotive, energy production, pharmaceuticals, and HVAC systems. Their widespread use has made them a primary choice for monitoring and controlling pressure in these industries.

-

Reliable and Stable Design: The PG13-DPG gauges are made from high-quality materials that ensure long-lasting performance and high efficiency. The piston design ensures that these gauges can provide stable and reliable performance over an extended period. This feature is highly important for industries that require tools with a long lifespan.

-

Easy Installation and Use: The piston differential pressure gauges are easy to install and set up. Their simple, user-friendly design ensures that they can be easily operated, even by individuals with limited technical experience. This feature has made them a popular choice across various industries.

Industrial Applications of PG13-DPG Piston Differential Pressure Gauges

-

Oil and Gas Industry: In the oil and gas industry, PG13-DPG piston differential pressure gauges are used to monitor and control pressure in pipelines and various equipment. These tools are vital for preventing leaks or damage to high-pressure systems.

-

Automotive Industry: In the automotive industry, PG13-DPG gauges are used to measure pressure in hydraulic and pneumatic systems of vehicles and heavy machinery. These tools are essential for ensuring the proper functioning of hydraulic systems in these industries.

-

Heating and Ventilation Systems: These gauges are used in heating, ventilation, and air conditioning (HVAC) systems to monitor and control pressure in compressed air and various gas systems. The accuracy of these gauges helps prevent malfunctions and extends the lifespan of equipment in these systems.

Conclusion

Differential pressure gauges are essential tools in many industries that require accurate pressure difference measurements. With features such as high accuracy, resistance to harsh conditions, easy installation and use, and reliable design, these gauges are an ideal choice for critical applications in various industries. These devices are generally efficient tools for controlling and monitoring pressure systems in both industrial and commercial environments.