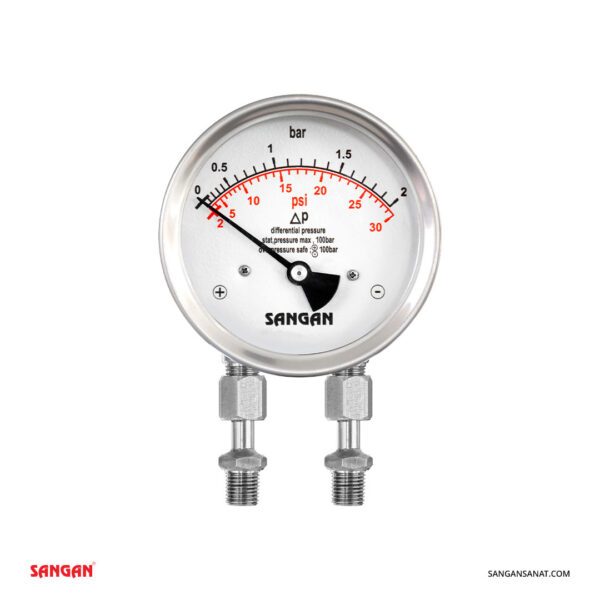

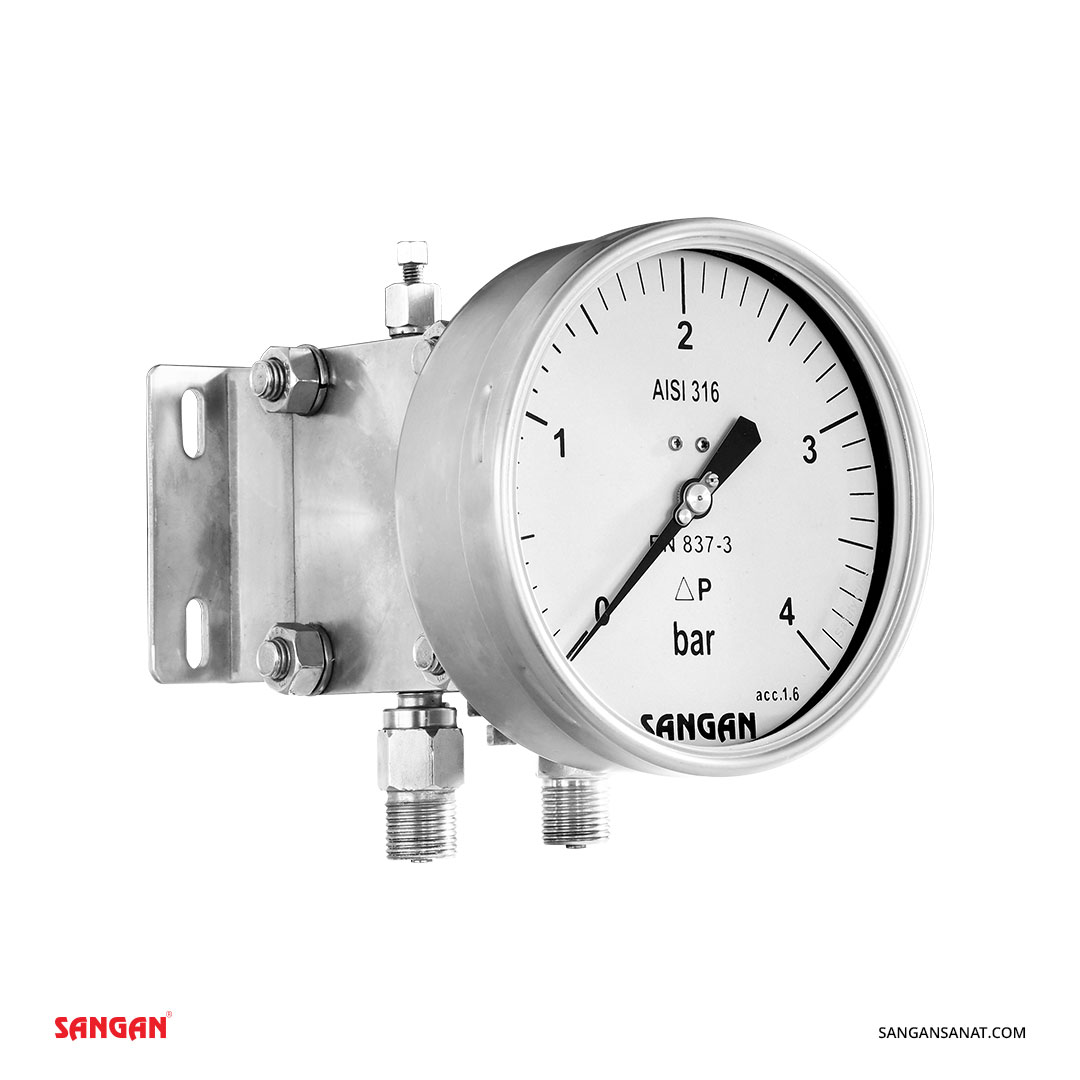

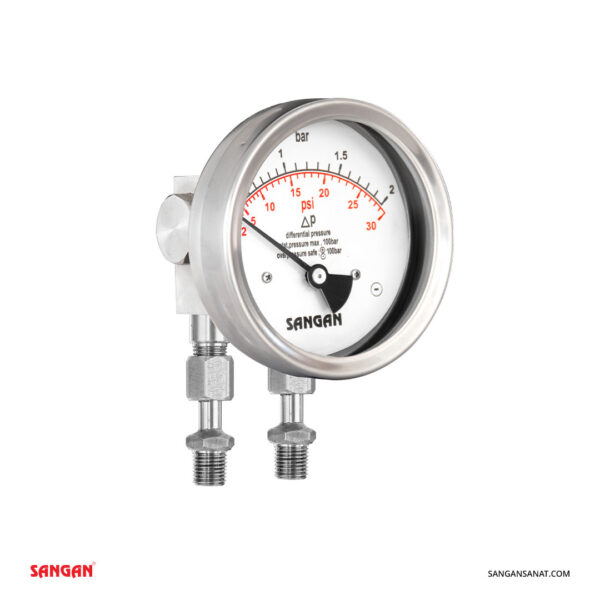

Diaphragm Differential Pressure Gauge PG13-362

The Diaphragm Differential Pressure Gauge PG13-362 is a widely used and precise instrument for measuring differential pressure in industrial and commercial systems. Designed with a specialized diaphragm mechanism, this gauge is ideal for monitoring and controlling pressure in various conditions. In this article, we will explore its functionality, advantages, applications, and key features to help you make an informed choice.

Functionality

This device operates based on diaphragm technology, which converts pressure variations into mechanical movement or measurable signals. The diaphragm, as the primary component, flexes in response to the pressure difference on either side. These changes are then accurately displayed through the internal mechanism. The simple yet advanced operation of this gauge makes it a preferred choice for industries requiring precise pressure measurement.

Advantages of the PG13-362 Diaphragm Differential Pressure Gauge

-

High Accuracy

The diaphragm design ensures high-precision differential pressure measurement, which is crucial for industries requiring accurate pressure control. -

Chemical Resistance

Made from corrosion-resistant materials, this gauge is highly durable in chemical and petrochemical environments, making it an ideal choice for oil, gas, and chemical industries. -

Suitable for Low Pressure Measurement

Specifically designed for low differential pressure applications, making it ideal for HVAC systems and laboratory setups. -

Safe and Stable Design

Built with high-quality materials and a robust structure, this gauge offers long-lasting performance, making it suitable for long-term industrial use. -

Easy Maintenance

The simple design and high-quality components reduce the need for frequent maintenance and repairs, saving time and operational costs.

Applications of the PG13-362 Diaphragm Differential Pressure Gauge

-

Chemical & Petrochemical Industries

Used for monitoring chemical processes and gas pressure levels, offering superior corrosion resistance for enhanced safety and efficiency. -

HVAC Systems

Employed in airflow measurement and regulation, improving system efficiency and energy savings. -

Food & Pharmaceutical Industries

Ensures precise pressure control, maintaining product quality and hygiene standards. -

Laboratory Systems

Used in low-pressure environments for accurate and sensitive testing. -

Power Generation

Applied in power plants and energy facilities for monitoring pressure in turbines and energy transmission systems.

How to Choose the Right Differential Pressure Gauge

Selecting the appropriate gauge requires considering factors such as:

- Pressure range

- Environmental conditions

- Industrial requirements

The PG13-362 gauge is an ideal choice for various applications due to its wide measurement range and high resistance to harsh conditions. Additionally, choosing the right diaphragm type and material ensures compatibility with specific media under pressure.

Installation & Maintenance

This gauge is easy to install without requiring specialized skills. To maintain optimal performance and longevity, consider:

- Keeping the device clean

- Regularly inspecting the diaphragm

- Avoiding mechanical shocks

Periodic maintenance and inspection can significantly extend the lifespan of this gauge.

Conclusion

The PG13-362 Diaphragm Differential Pressure Gauge is a reliable tool for monitoring and controlling pressure in various systems. With high accuracy, chemical resistance, a safe design, and broad industrial applications, it stands out as a top choice for both industrial and commercial settings. By making an informed selection and following proper maintenance practices, you can maximize efficiency and ensure long-term, reliable operation.