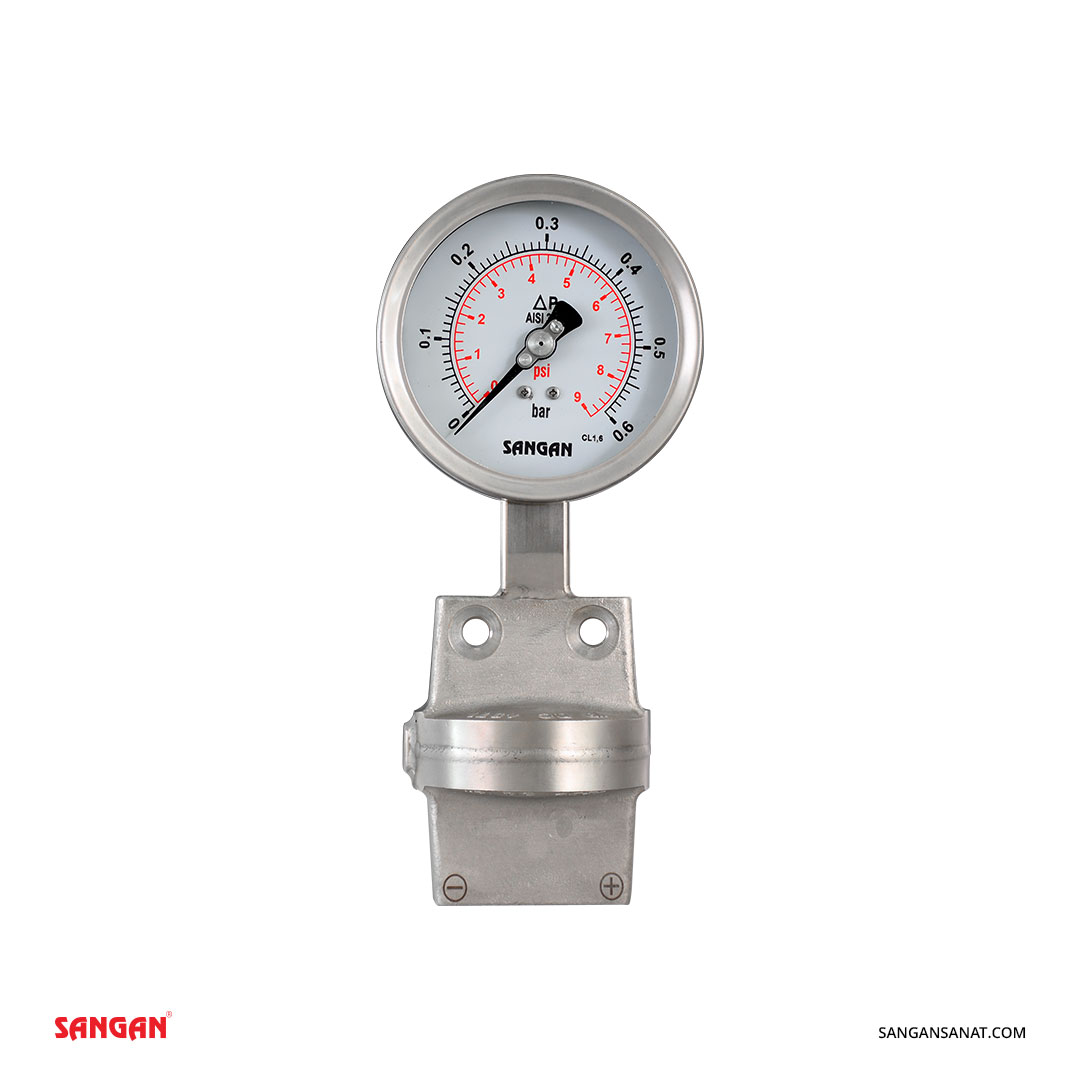

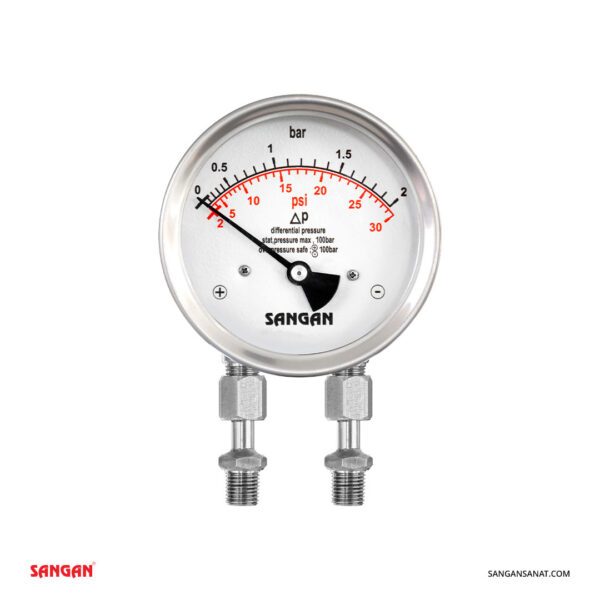

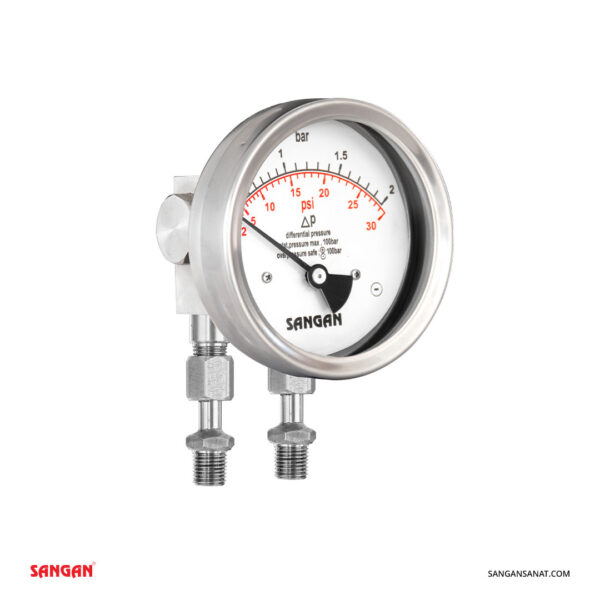

Diaphragm Differential Pressure Gauge PG13-700

The PG13-700 Diaphragm Differential Pressure Gauge is an essential instrument in various industries, designed to measure differential pressure in sensitive systems. Utilizing advanced diaphragm technology, this device offers high accuracy and reliable performance, even in harsh industrial environments. This article explores its functionality, benefits, applications, and key features to help you make an informed choice.

Functionality

This gauge features a highly sensitive diaphragm that deforms in response to pressure differences on either side. These changes are then converted into precise pressure readings and displayed on the gauge. The diaphragm-based design allows for simultaneous measurement of both low and high differential pressures, making it ideal for a wide range of applications.

Advantages of the PG13-700 Diaphragm Differential Pressure Gauge

-

High Measurement Accuracy

The diaphragm design ensures precise differential pressure measurements, especially in complex industrial environments such as pipelines and laboratory equipment. -

Corrosion and Chemical Resistance

Made from highly durable materials resistant to chemicals and corrosive substances, this gauge is suitable for use in chemical and petrochemical industries. -

Long Lifespan and Durability

Constructed with high-quality components and a robust design, the PG13-700 offers an extended lifespan, reducing long-term maintenance costs. -

Safe and Reliable Design

Engineered according to industrial standards, this gauge guarantees safe operation in various conditions, including high-pressure and extreme temperature environments. -

Versatile Compatibility

Designed for optimal performance across various industrial settings, from HVAC systems to complex chemical processing plants.

Applications

Oil, Gas, and Petrochemical Industries

Precise differential pressure measurement is crucial in pipelines and essential equipment. The PG13-700 offers high accuracy and chemical resistance, making it ideal for these applications.

Chemical Industries

For processes requiring accurate pressure monitoring in hazardous conditions, this gauge delivers reliable performance, ensuring safety and efficiency.

HVAC Systems

Used to monitor differential pressure in heating, ventilation, and air conditioning systems, contributing to improved efficiency and energy savings.

Power Plants and Energy Production

Accurate pressure monitoring in power generation systems is essential. The PG13-700 ensures reliable pressure measurement for safe and efficient operations.

Food and Pharmaceutical Industries

Precision and safety are critical in these industries to maintain product quality and compliance with health standards. The hygienic design of this gauge makes it a suitable choice.

How to Choose a Diaphragm Differential Pressure Gauge

Selecting the right gauge requires considering factors such as pressure range, operating environment, and material compatibility. The PG13-700 offers high adaptability and resistance to temperature variations and harsh conditions, making it a reliable choice for diverse industrial applications.

Maintenance and Repair

One of the key benefits of the PG13-700 is its low maintenance requirements. However, to ensure optimal performance:

- Regularly clean the device.

- Protect it from mechanical impacts.

- Inspect the system for leaks or potential damage.

Proper maintenance extends the device’s lifespan and reduces additional costs.

Conclusion

The PG13-700 Diaphragm Differential Pressure Gauge is a reliable and essential tool for accurately measuring differential pressure in industrial and commercial environments. Its high precision, durability, safety features, and extended lifespan make it an excellent choice for various industries. By choosing this gauge, you ensure flawless performance and accurate results in your systems.