فهرست مطالب

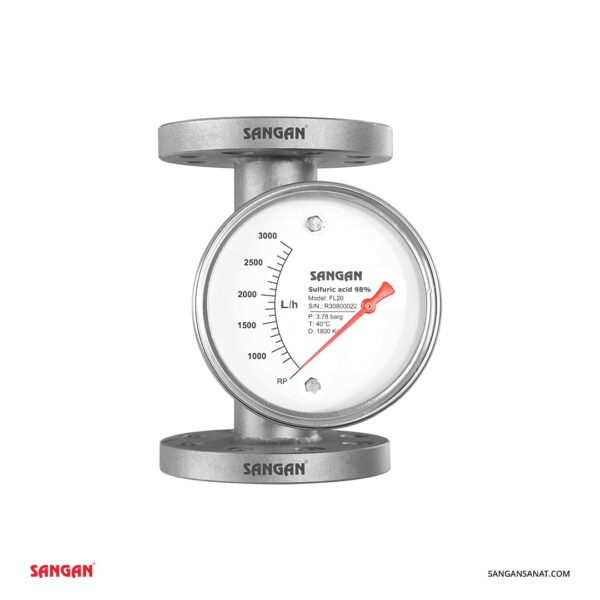

Gas Turbine Flowmeter FL98

The FL98 gas turbine flowmeter is an advanced instrument for measuring gas flow rates, widely used in industries such as oil, gas, and petrochemicals. This device operates based on the physical principle of turbine rotation. Simply put, when gas flows over the turbine blades, the turbine begins to rotate. The rotational speed of the turbine is proportional to the gas flow rate, allowing the flow rate to be calculated by measuring the turbine’s speed.

This flowmeter is particularly suitable for measuring the flow rate of clean gases and low-viscosity liquids. Accurate gas flow measurement in various systems, such as gas transmission and industrial processes, is of great importance, and the FL98 gas turbine flowmeter provides precise measurements.

This article explores the features, advantages, and applications of the FL98 gas turbine flowmeter, explaining its functionality and characteristics.

Operating Principle

The FL98 gas turbine flowmeter works by utilizing turbine rotation to measure gas flow. In this device, gas flows over a turbine, causing it to rotate. The rotational speed of the turbine is directly related to the gas flow rate. By measuring the turbine’s speed, the gas flow rate can be determined. This process is simple yet highly accurate, enabling precise measurement of different gas flow rates.

Gas turbine flowmeters are especially suitable for measuring the flow rate of clean gases and low-viscosity liquids such as water, alcohol, and other thin fluids. These flowmeters use sensors to accurately measure the turbine’s rotational speed and convert it into a flow rate value.

Features of the FL98 Gas Turbine Flowmeter

High Accuracy in Gas Flow Measurement

One of the key advantages of the FL98 gas turbine flowmeter is its high accuracy in measuring gas flow rates. This device can precisely measure various gas flow rates without being significantly affected by pressure or temperature changes. This makes the FL98 an ideal choice for sensitive industries such as oil and gas.

Simple Design with Minimal Maintenance Requirements

The FL98 turbine flowmeter is designed to require minimal maintenance and repairs. Due to its use of simple mechanical components, particularly durable turbine blades, this device has a long lifespan and low maintenance costs.

Non-Contact Operation with the Fluid

In the FL98 gas turbine flowmeter, there is no direct contact between the internal components and the fluid. This feature extends the device’s lifespan and minimizes the need for maintenance and repairs. It is particularly effective in chemical and gas industries where corrosive fluids are present.

Suitable for Clean Gases and Low-Viscosity Liquids

The gas turbine flowmeter is specifically designed for measuring the flow rate of clean gases and low-viscosity liquids. It accurately measures the flow of natural gas, oxygen, nitrogen, and other industrial gases that contain no suspended particles.

Easy Installation and Setup

The FL98 flowmeter features a compact and simple design, making installation and setup quick and easy. It can be seamlessly integrated into existing systems without requiring major structural modifications. The quick and simple installation reduces installation costs and system downtime.

Applications

The FL98 gas turbine flowmeter is used in various industries for measuring the flow rate of gases and low-viscosity liquids. Some of its key applications include:

Oil and Gas Industry

A primary application of gas turbine flowmeters is in the oil and gas industry. This device is used to measure the flow rate of natural gas and other industrial gases in pipeline systems, extraction and transmission processes, and pressure stations. Its high accuracy and stable performance make it a fundamental tool in the oil and gas sector.

Petrochemical Industry

In the petrochemical sector, gas turbine flowmeters are used to measure the flow rate of chemical gases such as propane, butane, methane, and other industrial gases involved in petrochemical production. Its high precision and ability to operate under various conditions make the FL98 highly valuable in this field.

Power Generation and Energy Industry

In power plants and electricity generation systems, the gas turbine flowmeter measures the flow rate of gases used in power production. It is particularly useful for measuring the flow of fuel gases such as natural gas and other fossil gases used in turbines and furnaces.

Food and Beverage Industry

In the food and beverage industry, the FL98 gas turbine flowmeter is used to measure gases such as carbon dioxide (CO₂), which is essential for carbonation in beverages and packaging processes. This flowmeter ensures precise measurement of food-grade gases.

Pharmaceutical Industry

In the pharmaceutical industry, the FL98 gas turbine flowmeter is utilized for measuring various gases used in the production of medicines and vaccines. Given the importance of precision in this industry, the FL98 is a preferred choice due to its high accuracy and stable performance.

Advantages of the FL98 Gas Turbine Flowmeter

- High accuracy in gas flow measurement

- Simple design with minimal maintenance requirements

- Non-contact operation with the fluid for increased durability

- Suitable for clean gases and low-viscosity liquids

- Easy installation without major system modifications

Conclusion

The gas turbine flowmeter is one of the most accurate and efficient instruments for measuring gas flow rates. With its high precision and exceptional features such as non-contact operation, simple design, and easy installation, it is widely used in industries such as oil and gas, petrochemicals, power generation, food, and pharmaceuticals. Due to its unique characteristics, the gas turbine flowmeter is an excellent choice for measuring gas flow rates and low-viscosity liquids.