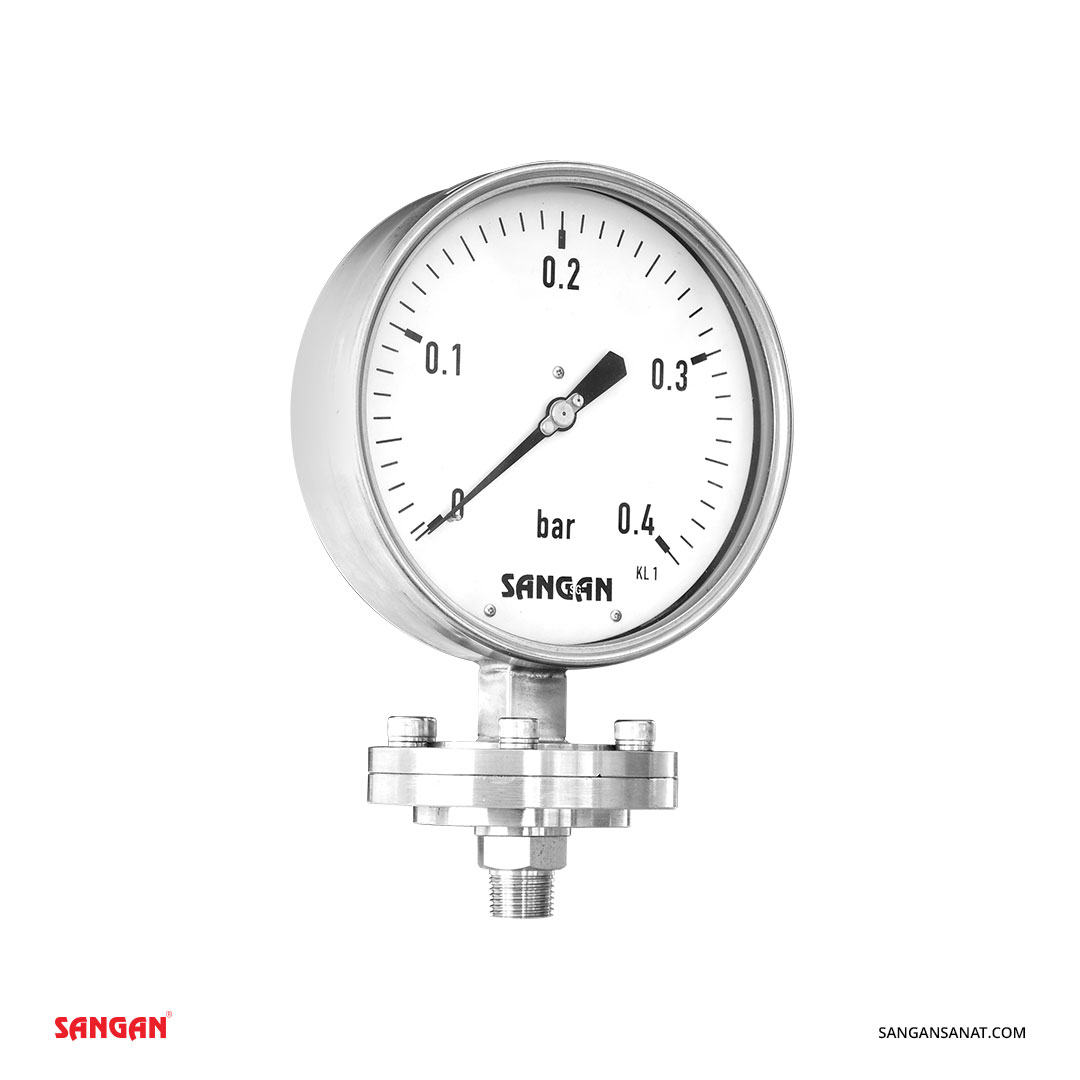

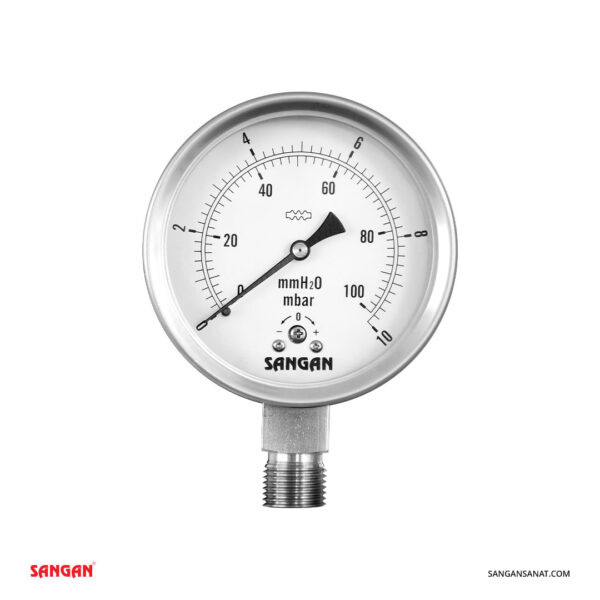

Diaphragm Pressure Gauge PG12

The Diaphragm Pressure Gauge PG12 is an advanced and precise tool designed for pressure measurement in sensitive industrial environments. It is particularly suitable for applications requiring accurate pressure measurement in corrosive environments, with high temperatures, or under severe pressure fluctuations. The PG12 diaphragm pressure gauge can effectively protect the pressure sensor and provide stable and accurate performance. In this article, we will explore the features and applications of the Diaphragm Pressure Gauge PG12.

Performance

The diaphragm pressure gauge uses a metal or plastic diaphragm that is directly affected by pressure. The pressure applied to the diaphragm causes it to deform, and this deformation is transmitted to a needle or digital display, which shows the pressure value. This design makes the gauge especially effective in harsh environments and resistant to corrosive materials and high pressures. The diaphragm of the PG12 pressure gauge is specifically designed for environments containing chemicals, oils, or corrosive materials.

Advantages of Using the PG12 Diaphragm Pressure Gauge

-

High Accuracy in Pressure Measurement

The PG12 diaphragm pressure gauge provides high accuracy in pressure measurement, thanks to its sensitive diaphragm. It can detect even small pressure changes and provide precise results, which is essential for sensitive industrial applications. -

Resistance to Corrosive Materials and Harsh Conditions

One of the standout features of the PG12 pressure gauge is its excellent resistance to corrosive materials such as acids and bases. This makes it highly suitable for use in the chemical, petrochemical, and pharmaceutical industries. It also performs well under high temperatures and severe pressures. -

Long Lifespan and Stable Performance

Due to the use of high-quality materials and a robust design, the PG12 pressure gauge has a longer lifespan. The diaphragms used in this gauge can measure pressure with high accuracy for extended periods. This feature reduces maintenance and equipment replacement costs. -

Easy and Quick Installation

The PG12 diaphragm pressure gauge is designed with a compact and easy-to-install structure for various systems. Installation is simple, and the device can be easily connected to pipes and pressure systems without requiring special expertise. -

Variety of Materials and Sizes

The PG12 pressure gauge is available in various materials and sizes, allowing for the selection of the best option for each type of system. Choosing the right materials for the diaphragm and body of the device increases its efficiency and lifespan.

Applications

-

Chemical and Petrochemical Industries

In chemical and petrochemical industries, which deal with corrosive and hazardous materials, the diaphragm pressure gauge can be used as a tool resistant to difficult conditions. This gauge protects pressure sensors from acids and bases and accurately measures system pressure. -

Food and Pharmaceutical Industries

In the food and pharmaceutical industries, where precise pressure control is essential in production processes, the PG12 pressure gauge is an ideal choice due to its high accuracy and sanitary design. It can be effectively used in processes where precise pressure is critical to product quality. -

Oil and Gas Industry

In the oil and gas industry, precise pressure control in equipment and pipelines is of great importance. The diaphragm pressure gauge can accurately measure pressure in these sensitive environments, preventing damage to equipment. -

HVAC Systems

The PG12 pressure gauge is also suitable for use in HVAC systems. It can precisely measure pressure in compressed air systems, helping to maintain optimal performance in these systems. -

Power Plants and Energy Production Systems

In power plants and other energy production systems, accurate pressure measurement in production processes is crucial. The PG12 pressure gauge can be used in these systems as a precise and durable tool.

How to Choose the Right Diaphragm Pressure Gauge

When selecting the most suitable diaphragm pressure gauge model, several factors should be considered:

- Type of Material in Contact (Corrosive or Non-corrosive)

- Pressure and Temperature Range

- Type of Application and Industrial Environment

Proper selection of these parameters can help optimize the performance of industrial systems and increase the lifespan of equipment.

Maintenance and Care of the Diaphragm Pressure Gauge

To maintain the performance of the diaphragm pressure gauge, it is essential to follow some key maintenance tips:

- Periodically check the device’s performance to ensure accurate measurements.

- Clean the diaphragm from contaminants and deposits.

- Avoid impacts on the gauge.

These tips will help ensure that the device maintains its performance over the long term and reduce maintenance costs.

Conclusion

The diaphragm pressure gauge is an essential and precise tool for pressure measurement in various industries. With features such as high accuracy, resistance to corrosive materials, long lifespan, and easy installation, this gauge is widely used in chemical, oil and gas, food and pharmaceutical industries, and other pressure-sensitive sectors. Choosing this gauge can improve system performance and reduce maintenance costs.