فهرست مطالب

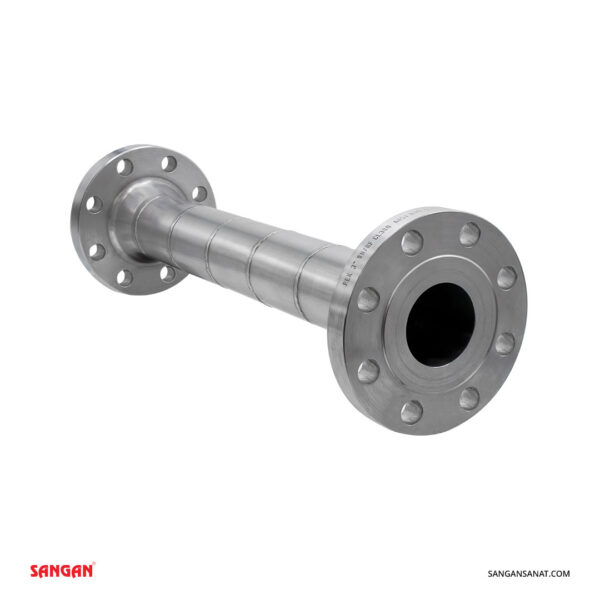

Orifice Plate FL30-40

The orifice plate FL30-40 is a widely used industrial device for measuring fluid flow. Designed to create a pressure differential in the fluid flow, it is an excellent choice for many industries due to its high accuracy and compliance with various standards. Below, we provide more details about this device and its applications.

How the Orifice Plate Works

The orifice plate creates an obstruction in the fluid path, reducing the flow cross-section and generating a pressure drop. This pressure differential is measured using instruments such as a differential pressure transmitter or a mechanical differential pressure gauge. The flow rate is then calculated based on standard formulas.

Common standards used for the design and implementation of orifice plates include:

- ISO 5167-2 – International standard for flow measurement using differential pressure devices.

- ASME – American mechanical standards applicable to orifice plate design.

- AGA – Gas flow measurement standards issued by the American Gas Association.

Main Components of the Orifice Plate FL30-40

The orifice assembly consists of the following components:

- Orifice Plate – A plate with a central hole that allows fluid to pass through. The hole size and shape vary depending on application requirements.

- Flange – Typically, a weld neck flange is used, though other types can be provided based on customer needs.

- Gasket – Ensures a secure seal and prevents leakage at the installation point.

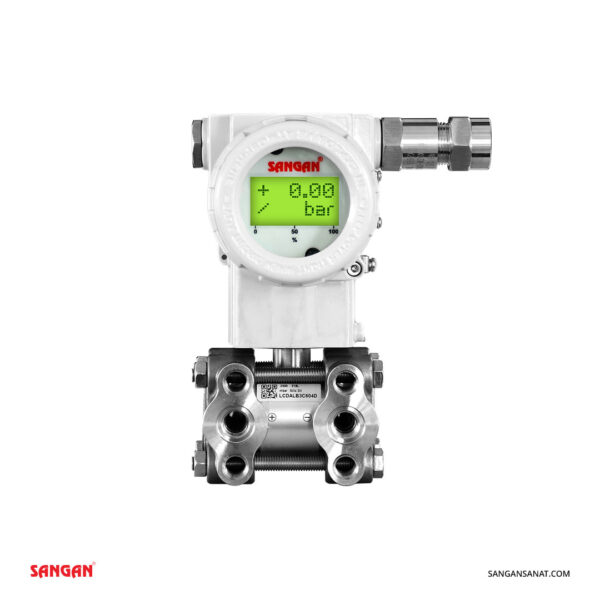

- Measurement Instruments – Includes differential pressure transmitters or sensors responsible for data collection.

Orifice Plate as a Flow Restrictor (Restriction Orifice)

In some applications, the orifice plate is used to limit fluid flow and create a pressure drop. In such cases, differential pressure measurement is not required, and the plate hole is designed to restrict flow to a specific value. This method is highly effective for flow rate control in industrial systems.

Advantages of Using the Orifice Plate

- Simple Design and Installation – Easy to install and use due to its straightforward design.

- Compliance with Various Standards – Can be designed based on different standards as per customer requirements.

- Cost-Effective – More economical compared to other flow measurement methods.

- High Durability and Resistance – Typically made from stainless steel or carbon steel, offering excellent resistance to pressure and corrosion.

- Versatile Applications – Suitable for industries such as oil, gas, petrochemical, water treatment, and more.

Applications of the Orifice Plate FL30-40

The FL30-40 orifice plate is designed for:

- Measuring the flow of liquids and gases.

- Pressure reduction and flow control in pipelines.

- Use in high-pressure environments.

- Industrial flow measurement systems.

- Compliance with international standards.

Orifice Plate Selection Guide

When choosing an orifice plate, consider the following factors:

- Fluid Type – Whether the fluid is gas or liquid significantly affects the plate design.

- Flow Range – The desired measurement range must be specified.

- Operating Pressure & Temperature – Material selection and design should match the operating conditions.

- Flange Type – Selection depends on the technical specifications of the system.

- Applicable Standards – The chosen standard should align with project requirements.

Conclusion

The Orifice Plate FL30-40 is an efficient device for fluid flow measurement and pressure control in industrial systems. Designed to meet recognized standards and adaptable to various conditions, it is a reliable choice for multiple industries. For more details and to download the catalog, please visit the Downloads section.