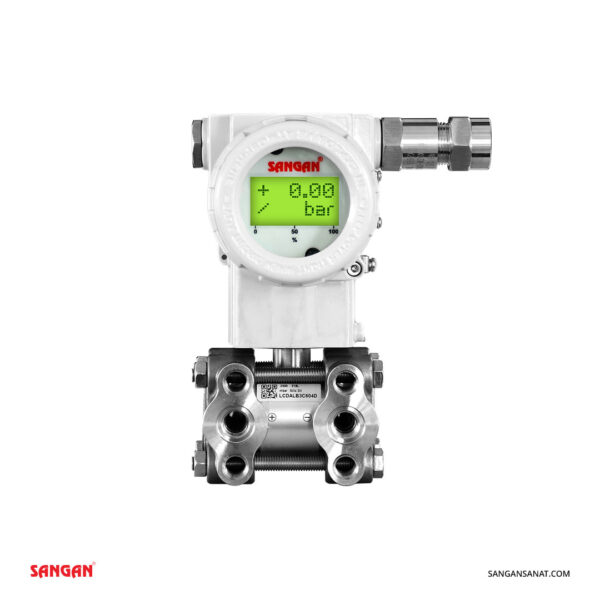

Differential Pressure Transmitter SPT1001

The SPT1001 Differential Pressure Transmitter is a crucial instrument used in various industries to measure the pressure difference between two points in a system. With its high accuracy and reliable performance, it plays a vital role in numerous industrial and engineering processes. Below, we provide a detailed overview of this device, its components, and its advantages.

Operation

The SPT1001 Differential Pressure Transmitter utilizes highly sensitive pressure sensors to measure the pressure difference between two points and convert it into a processable electrical signal. This signal can be used to calculate different parameters such as fluid flow rate, liquid levels in tanks, or the overall system pressure.

Main Components of the Differential Pressure Transmitter

- Pressure Sensor: The core component responsible for pressure measurement.

- Housing: Made from durable materials with high resistance to pressure and corrosion.

- Electronic Circuit: Processes the measured signals and converts them into standard outputs.

- Input Ports: Designed for connection to different pressure points within the system.

- Display: Some models include an internal display for real-time measurement readings.

Advantages of the Differential Pressure Transmitter

- High Accuracy: Ensures highly precise pressure measurements.

- Wide Industrial Applications: Used in oil, gas, petrochemical, power plants, and HVAC systems.

- Durable Design: Resistant to harsh environmental conditions, including high temperatures and pressures.

- Calibration Capability: Adjustable settings for different applications.

- Standard Output Signal: Provides industry-standard outputs such as 4-20mA for seamless integration with industrial control systems.

Applications

- Flow Measurement: Calculates fluid flow in pipelines using devices like orifice plates.

- Liquid Level Control: Ideal for monitoring tank levels in both open and closed systems.

- Pressure Monitoring: Ensures pressure regulation in complex systems.

- HVAC Systems: Controls and regulates airflow and gas distribution.

- Industrial Processes: Monitors differential pressure in filters, compressors, and other equipment.

Guidelines for Selecting a Differential Pressure Transmitter

When choosing the right differential pressure transmitter, consider the following factors:

- Pressure Range: Define the required pressure difference range.

- Fluid Type: Determine whether the fluid is gas or liquid, as this affects device selection.

- Operating Temperature and Pressure: Ensure compatibility with system conditions.

- Material Selection: Choose corrosion-resistant materials for specific environmental conditions.

- Accuracy and Response Time: Ensure the device meets the process requirements.

Conclusion

The SPT1001 Differential Pressure Transmitter is an essential tool for monitoring and controlling industrial processes. With its robust design and high efficiency, it enhances system performance and ensures precise measurements. Selecting the right model based on project-specific requirements guarantees optimal performance and long-term durability of the device