فهرست مطالب

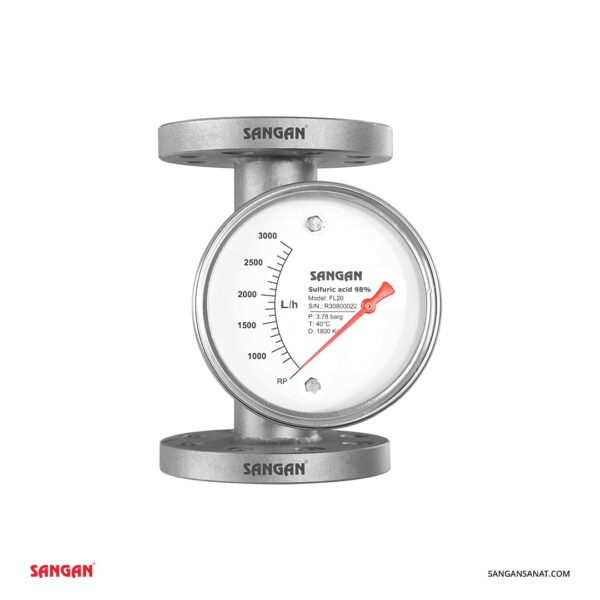

Glass Tube Rotameter FL10

The Glass Tube Rotameter FL10 is a precise and practical instrument for measuring the flow rate of fluids in various industries. This device uses a transparent glass tube through which the fluid flows, allowing easy measurement of the flow rates of liquids and gases. Due to its simple structure and ease of use, the Glass Tube Rotameter is widely used in many industries and has become an essential tool for controlling and measuring fluid flow. This article explores the features, advantages, and applications of the Glass Tube Rotameter FL10 and explains its role in improving industrial process performance.

Operation

The Glass Tube Rotameter FL10 is made of a transparent glass tube whose diameter increases from the inlet to the outlet. Inside this glass tube, there is a float or ball whose position along the tube indicates the fluid’s flow rate. Generally, the higher the flow rate, the higher the position of the float. By calibrating the glass tube, the operator can directly read the flow rate.

This device is precisely used in processes requiring accurate flow control. The FL10 rotameter is commonly used to measure the flow of liquids and gases over a wide range of flow rates. Since it typically uses glass tubes, the transparency of the tube allows the operator to easily observe the position of the float and measure the flow rate.

Features

-

High Accuracy in Fluid Flow Measurement

The Glass Tube Rotameter provides high accuracy in fluid flow measurement due to its simple and transparent structure. The movement of the float inside the glass tube directly represents the flow rate, and the operator can easily read the flow value. This feature makes it an excellent choice for systems that require high accuracy. -

Corrosion-Resistant Design

The glass tube of the FL10 rotameter is made of corrosion-resistant materials. This feature is particularly important in chemical and petrochemical industries where corrosive fluids are constantly flowing. The corrosion-resistant design ensures a long lifespan and optimal performance in harsh conditions. -

Metal Protective Cover to Shield Glass from Impacts

One of the important features of the Glass Tube Rotameter is the use of a metal protective cover. This cover effectively protects the glass from potential impacts. In industrial environments, the likelihood of hard objects coming into contact with equipment is high, and the metal cover protects the glass from physical damage and impacts. -

Option to Add Limit Switch

The FL10 rotameter can be equipped with a limit switch. Limit switches automatically activate when the fluid flow exceeds a specified range, sending alerts to the operator. This feature enhances safety and process control, making it especially useful in systems requiring continuous monitoring. -

Flow Rate Range of 10:1

The FL10 Glass Tube Rotameter can measure fluid flow in a range with a ratio of 10:1. In other words, this device can measure both low and high flow rates with high accuracy, making it ideal for processes with wide variations in fluid flow. This flow ratio allows the FL10 rotameter to perform well in various industries with different flow conditions.

Applications of Glass Tube Rotameter

Due to its high accuracy and durability, the FL10 Glass Tube Rotameter is used in various industries. Some of the most important applications include:

-

Chemical and Petrochemical Industry

In the chemical industry, the FL10 Glass Tube Rotameter is used to measure the flow of corrosive liquids and gases. Due to its resistance to corrosion and high accuracy, it is one of the primary choices for chemical processes. -

Pharmaceutical Industry

In the pharmaceutical industry, where accurate measurement of fluid flow is critical, the FL10 Rotameter can precisely measure the flow of liquids and gases. This makes it suitable for processes involving drug and vaccine production. -

Water and Wastewater Industry

In the water and wastewater industry, the FL10 Rotameter is used to measure the flow rate of water in various systems, such as pumps and treatment plants. Accuracy in measuring water flow is particularly important in water treatment systems. -

Oil and Gas Industry

In the oil and gas industry, accurate measurement of fluid flow is essential, especially in pipelines and storage tanks. The FL10 Glass Tube Rotameter is used as a precise and reliable tool in this industry. -

HVAC Systems

In HVAC systems, accurate measurement of airflow and gases is crucial for controlling temperature and humidity. The FL10 Rotameter is used as an effective tool to measure the flow of gases and air in these systems.

Important Considerations for Using the FL10 Glass Tube Rotameter

-

Installation in a Vertical Position

For optimal performance, the FL10 Glass Tube Rotameter must be installed vertically so that the float can move correctly and the flow rate can be accurately measured. -

Periodic Calibration

To ensure accurate measurement, it is recommended that the device be periodically calibrated. The FL10 Rotameter is tested and calibrated by the manufacturer, and it can be calibrated with the specific fluid required by the customer. -

Protection from Impacts

In industrial environments, the Glass Tube Rotameter may be exposed to impacts and physical damage. Using a metal protective cover can effectively shield the glass from potential damage.

Advantages of Using the FL10 Glass Tube Rotameter

- High accuracy in fluid flow measurement

- Resistance to corrosion and physical damage

- Ability to add limit switches for alerts in specific flow rates

- Flow range of 10:1 for accurate measurement in varying conditions

- Simple and practical design that makes it easy to use

Conclusion

The FL10 Glass Tube Rotameter is a precise and efficient tool for measuring fluid flow in various industries. With features such as high accuracy, corrosion resistance, the ability to add limit switches, and impact-resistant design, this device can provide optimal performance across a wide range of industrial processes. Using this rotameter in chemical, pharmaceutical, oil and gas, water and wastewater, and HVAC industries can help improve process control and increase efficiency.