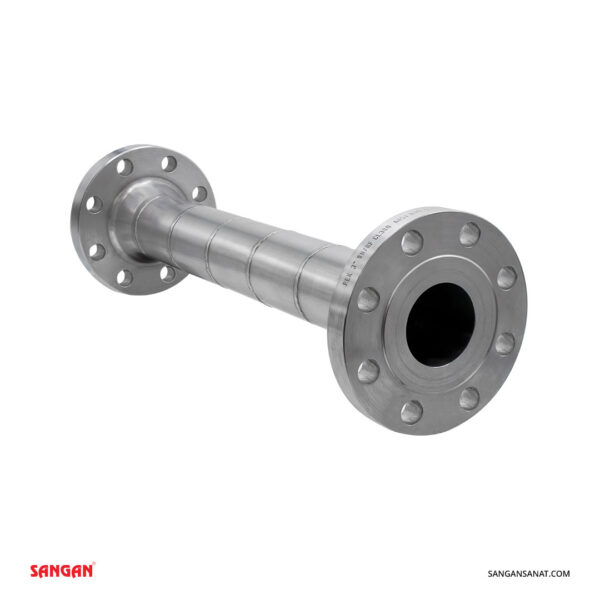

In hydraulic systems and pipelines, precise pressure drop control is a major challenge that engineers must manage. When a significant pressure drop is required, a single restriction orifice plate may not be sufficient. In such cases, more advanced systems like multi-stage restriction orifice assemblies are used. This article explores the FL42 multi-stage restriction orifice and its key features.

What is the Multi-Stage Restriction Orifice?

The FL42 multi-stage restriction orifice is an advanced type of restriction orifice plate consisting of multiple orifice plates. These plates are designed to gradually reduce fluid pressure in multiple stages, ensuring an optimal pressure drop across the system. Compared to single orifice plates, multi-stage designs help prevent issues such as noise, choking, and cavitation.

How Does the Multi-Stage Orifice Work?

A multi-stage restriction orifice consists of multiple orifice plates, each responsible for reducing the fluid pressure at a specific stage. As the fluid passes through each plate, a portion of the pressure is reduced, preventing sudden drops that could cause damage.

For example, when the fluid enters the first orifice plate, part of its pressure is reduced. The fluid then moves to the second stage, where further pressure reduction occurs. This process continues until the pressure reaches the desired level.

Key Features of the FL42 Multi-Stage Orifice

- Gradual Pressure Reduction: Enables controlled and smooth pressure drop, preventing sudden changes that could cause system failure.

- Noise Reduction: Prevents excessive noise caused by rapid pressure changes in hydraulic systems.

- Choking Prevention: Ensures uninterrupted fluid flow, preventing restrictions that could disrupt operations.

- Cavitation Prevention: Reduces the risk of cavitation by avoiding abrupt pressure drops that lead to vapor bubble formation.

- Extended Equipment Lifespan: Reduces mechanical damage and lowers maintenance costs by preventing common pressure-related issues.

Advantages of Multi-Stage Orifice Plates Over Single Orifices

- Reduced Risk of Failure: Single orifice plates may cause sudden pressure drops, leading to system damage, whereas multi-stage orifices prevent this risk.

- More Precise Pressure Control: Ideal for applications requiring high-pressure drops with minimal system impact.

- Protection Against Equipment Damage: By maintaining a gradual pressure reduction, equipment lifespan is extended.

- Lower Maintenance Costs: Reduces repair and maintenance expenses by preventing system failures caused by sudden pressure variations.

Applications

The FL42 multi-stage restriction orifice is widely used in industries such as:

- Oil & Gas

- Petrochemical & Refining

- Water Treatment

- Hydraulic Systems

This orifice assembly is particularly useful in applications where precise pressure control is required for high-flow fluids or systems with significant pressure fluctuations.

Conclusion

The FL42 multi-stage restriction orifice is an advanced and efficient solution for controlling pressure drops in hydraulic and pipeline systems. By gradually reducing pressure, it prevents issues such as noise, choking, and cavitation while extending the lifespan of equipment and reducing maintenance costs. If you need an effective way to manage pressure drop in your system, the FL42 multi-stage restriction orifice is an excellent choice.